In clean water and wastewater applications, all pumping systems require a check valve to prevent reverse flow when the pump is not in operation. Check valves operate automatically, require no external power or control signal and operate from the change in flow direction.

The selected check valve should also have a long life, nonslam closure, low head loss and low leakage. While there are many types of waterworks check valves including silent checks, double discs, swing checks, ball checks and tilted discs, historically the swing check valve has been the most prevalent.

Traditional Swing Check Valves

The traditional swing check valve is not without its faults. The valve is defined in American Water Works Association (AWWA) standard C508 and is designed to close tight and prevent back spinning of the pump after shutoff. Traditional swing check valves have 90-degree seats with long strokes that can produce slamming, especially in vertical pipe installations.

These valves are outfitted with a wide array of accessories to prevent slamming, which are beyond the scope of AWWA C508. Probably the most common accessory is a lever and weight. While it is normally assumed that the weight makes the valve close faster, it actually reduces slamming by limiting the stroke of the disc, but in return, may cause a substantial increase in head loss.

The valve closure is also slowed by the inertia of the weight itself and the friction of the stem packing. There is a risk of injury from sudden movement of the weight; so, users may also want a safety cage around the lever and weight.

An air cushion is sometimes used to slow the impact of the valve closure to reduce slam. Everyone has experienced the effect of an air cushion on a slamming storm door. But the conditions in a water pipeline are different. When a door slams, its momentum is smoothly absorbed by the air cushion because as the door slows, the forces from the closing spring and outside wind become less.

Conversely, when a check valve in a water pipeline closes, the reverse flow quickens at a tremendous rate so that every fraction of a second that the valve closure is delayed, the forces on the disc will increase by an order of magnitude.

In practice, the air cushion holds the disc open long enough for the reverse flow to intensify and slam the disc even harder into the seat. Since air cushions are based on the use of air, they provide little positive restraint of the closing disc and cannot counteract the enormous forces being exerted by the reverse flow.

A more effective accessory for dampening swing check valve motion is an oil cushion, also known as an oil dashpot. Because oil is incompressible, the oil cushion will counteract high forces exerted on the disc by the reverse flow and properly control the last 10 percent of valve closure.

However, the pump must be capable of withstanding significant backflow because the oil dashpot will allow the check valve to pass a portion of the reverse flow back through the pump. Since the reverse flow forces on the valve disc are extremely high, the oil pressure often exceeds 2,000 pounds per square inch gauge (psig), causing valves with these devices to be costly.

The high-pressure oil cylinder is expensive and because it puts the valve stem under high loads, a special check valve with a large diameter stem is needed. If the pipeline contains debris or sewage, a check valve with oil cushion can act as a screen during reverse flow conditions and quickly clog the line. Despite their drawbacks, traditional waterworks swing check valves are still specified and used about 20 percent of the time.

Resilient Hinge Check Valves

The newest type of swing check valve listed in AWWA C508 is the resilient hinge check valve. The swing action occurs from flex action in the rubber-molded disc instead of rotation about a hinge pin. The valve can have greater reliability with no hinge pin, packing, weight or lever. The resilient hinge check valve has virtually no maintenance because the only moving part is the disc.

The resilient hinge check valve has a full port slanted at a 45-degree angle, which provides a short 35-degree stroke, quick closure and low head loss. This valve is often slam free. In cases of high head or vertical pipe installation, the valve can be equipped with an internal spring for faster closure, which provides nonslam characteristics.

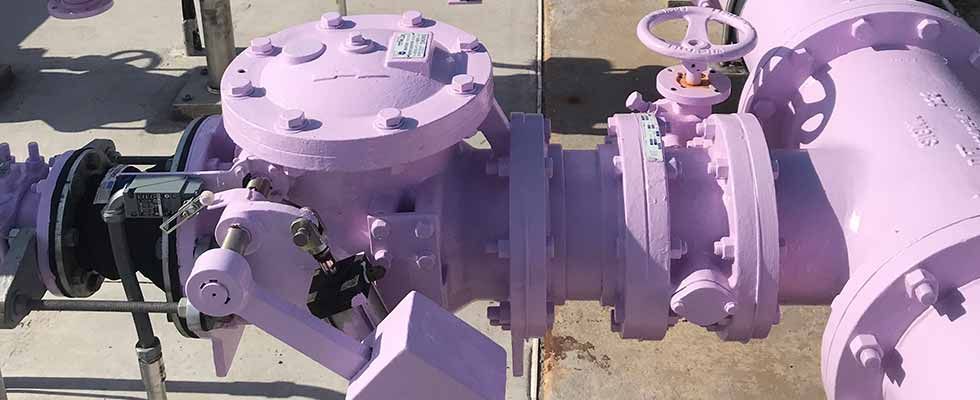

In Image 2, an 8-inch resilient hinge check valve with internal spring was used to replace a traditional swing check valve in a wastewater vertical pipe. The slam was eliminated, and the valve design did not require external weights, levers and springs.

The resilient hinge check valve comes standard with a fusion bonded epoxy (FBE) coating, which serves as the mating seat in the valve and provides corrosion resistance. The disc is steel and fully encapsulated with molded rubber. The valves are available with mechanical position indicators and limit switches to display valve position in the vicinity or at a remote control facility.

If inspection is needed, the top cover is removable to provide full access to the disc and body interior. There are no hinge pins, packing or bearings to maintain. Resilient hinge check valves can provide nonslam closure with corrosion resistance and no externally moving parts.