These valves can alleviate a variety of pump system issues.

Pipe bursts due to transients and surges are common. Not only are the maintenance costs of these repairs high, but when adding possible litigation for third party damages combined with the potential cost of water loss, another pipe burst can have big consequences.

Surges, or transients, are the result of a rapid change in liquid mass velocity within a pipeline. This kinetic energy, released as pressure, acts to expand the pipe diameter and can destroy fittings, pipes, valves, instrumentation and pumps. Pressure waves travel the length of the pipeline of the offending device, then reverse direction. The waves move at a constant speed until they meet a barrier. The reflected and incident waves may superimpose each other to produce a more compounded wave pattern that includes double peaks and double troughs. The consequence of improper protection from surges or transients could be a pipe burst or equipment failure and result in damage, water loss or litigation.

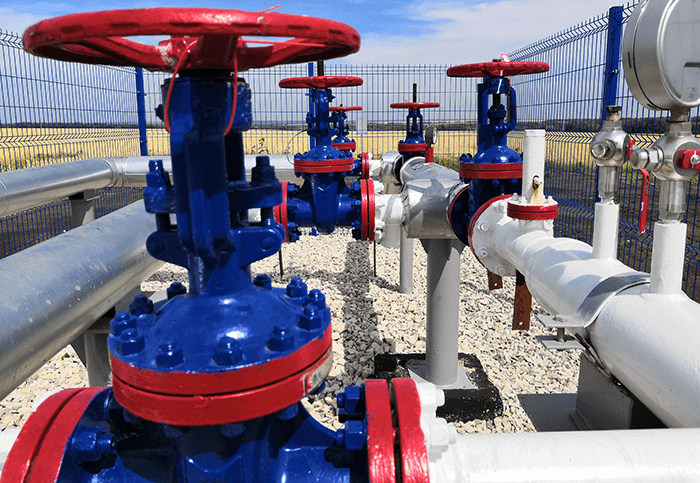

Transients, surges and the resulting pipe bursts can be caused by numerous events: loss of power at a pump station, pump station programmable logic controller (PLC) malfunction, single-speed pump motors without adequate pump control valves or the rapid closure of isolation valves.

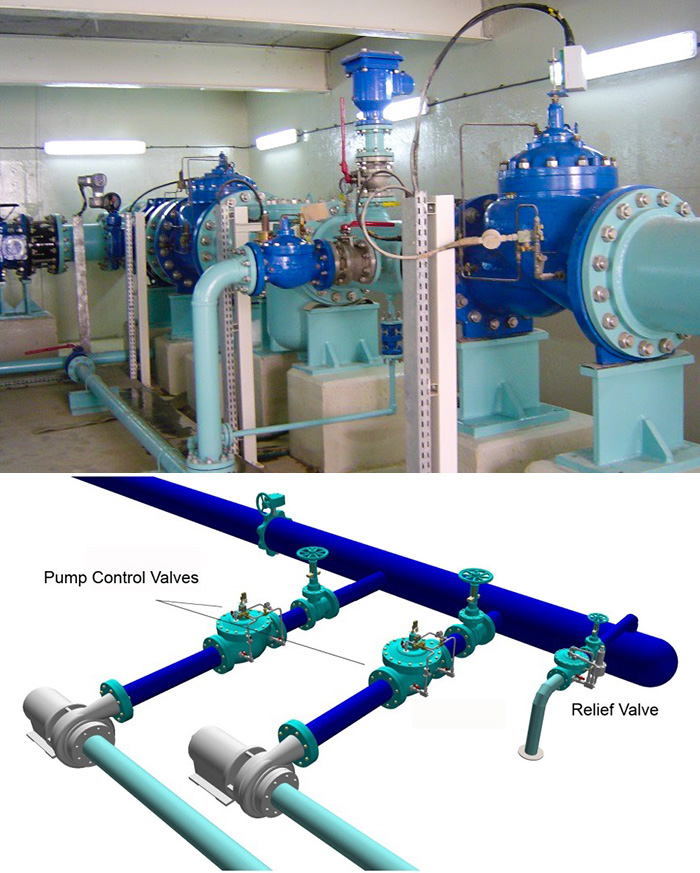

The selection and sizing of pressure relief valves is very important to protect pipelines, piping equipment and pumps. The application and selection of relief valves may require a detailed analysis by a transient specialist who looks at all factors before making an informed choice. Pressure relief valves do not have to be limited to pump stations and can be strategically located anywhere in the distribution system to deal with overpressures and transients. The pressure relief valve is normally mounted off a tee on the header or mainline and opens under high pressure to discharge the relief flow to atmosphere or other suitable low-pressure zone.

It is important to consider the discharge that is released from the relief valves when they react to the overpressure. The discharge can often be chlorinated, which poses a threat for fish-bearing streams, landscaping, etc. A well-considered approach to the proper management of the discharged relief water is always required.

A good initial guideline for sizing a relief valve is to base the flow rate capacity of the valve at 25 percent of the maximum flow in the main pipeline. It is important that the relief valve be sized so as not to be too small or too large. An undersized relief valve will not have enough capacity to relieve the overpressure while an oversized valve will result in excessive flow and possibly a non-recoverable pressure loss.

Pressure relief valves are typically used where there is a risk to the system of higher pressure occurring, and frequently used in systems that have pumps. Their selection and sizing is determined on whether a simple over pressure protection is required, or if there is risk of transients, in which case a surge anticipating relief valve may be selected.