Many times, valve problems are not a function of the valve at all, but stem from problems with the piping system design, valve location, poor installation practices or selecting the wrong valve for the application.

The following information is a guideline of valve basics.

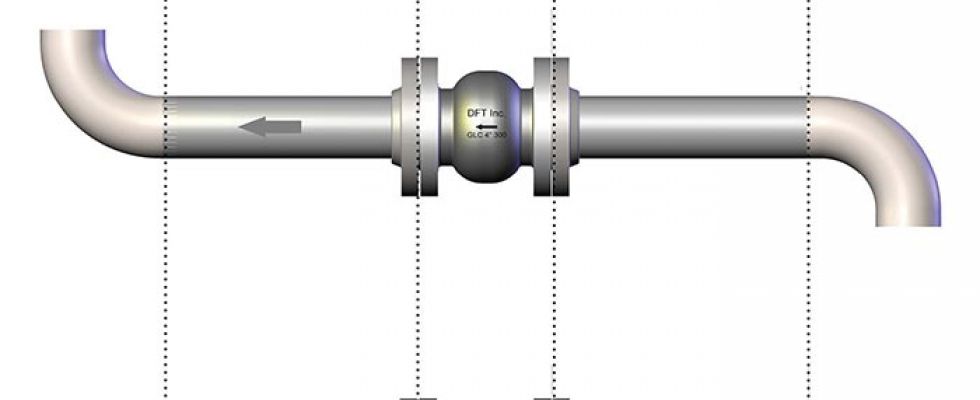

Rule No. 1: All valves work best when installed in a nonturbulent flow condition. Strive for smooth, nonturbulent flow in all design cases. Five times the NPS (nominal pipe size—outside diameter [OD] of a pipe) of straight pipe both upstream and down is recommended, but some valve designs can be installed with less straight pipe than that. Acceptability of nonlinear piping is case specific. It is always a good idea to consult the valve manufacturer; they will be able to give guidance to avoid future maintenance problems.

Rule No. 2: Use flow calculations to properly size.

Properly sized check valves are essential for optimum system performance with minimum required maintenance. Performing the flow sizing calculations for check valves is as important as doing the sizing calculations for every on/off or control valve in the system. The rules for sizing on/off valves do not apply to check valves, nor do the sizing rules for control valves apply either. Check valves must have a flow coefficient (Cv) less than the Cv calculated when using the desired pressure drop in the flow sizing equations.

Rule No. 3: Find the proper placement.

A common question is whether horizontal versus vertical line placement matters. A horizontal line is always preferred, because it takes gravity out of the equation. While many styles of check valves will work in horizontal piping, axial flow, or silent, check valves are typical in vertical piping.

If pumps, elbows, expansion joints and other valves are upstream of a valve, it can cause turbulence, which can lead to instability of the disc and ultimately lead to wear and component failures.