Wastewater pumps perform a behind the scenes, yet critical, job that most people do not think about. They are found in lift stations and wastewater treatment plants doing their job day in and day out.

Yet, if a user comes across an experienced wastewater operator and asks what they like or dislike about the pumps, the operator will have a must-have list of features that keep the station running.

Types of Pumps

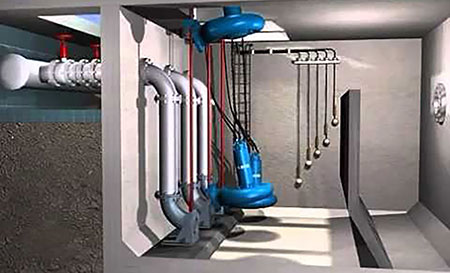

Submersible pumps

Submersible pumps are designed to operate in wastewater. A close-coupled sealed motor allows for complete submergence, eliminating the need for a separate dry-well, which can decrease installation costs.

Submersible pumps typically feature dual oil-lubricated mechanical seals with moisture sensing probes and an associated alarm relay. An alarm sounds when it detects water in the oil chamber. This sensor protects against moisture entering the motor and causing issues by alerting the operator to the seal failure.

Since submersible pumps are installed in wastewater wet wells, access to the pumps is limited. Operators must remove the pump via the guide rail system to inspect or service the equipment.

Dry-pit pumps

Dry-pit pumps are installed next to a wet well or sump. This allows for the use of a nonclog centrifugal pump and motor.

Solids-handling impellers will pass many types of solids. They can be mounted vertically or horizontally, allowing flexibility for space constraints within the dry-pit vault. Dry-pit pumps keep the pump out of the wastewater, allowing for personnel to easily diagnose a pump during operation. Working on a pump that is not covered in sewage minimizes safety risks.

A downside of the dry-pit pump is the possibility of flooding. Water in the dry-pit would destroy standard pump motors.

If the dry-pit is susceptible to flooding, a dry-pit submersible pump might be an option. These are similar, if not identical, to the submersible pumps discussed before. Traditional submersible pumps use wastewater to cool the motor. In a dry-pit application, there is no surrounding fluid to use for cooling. Therefore, submersible dry-pit pumps have oil-filled submersible motors and/or cooling jackets to provide adequate cooling and insurance against inadvertent dry-pit flooding.

Self-priming pumps

Self-priming pumps are an aboveground alternative to submersible or dry-pit pumps. Designed for suction lift applications (like lift stations), self-priming pumps prime by extracting air from the suction side and discharging it back into the wet well.

Once primed, this pump operates the same as standard solids-handling centrifugal pumps.